Commitment to Sharpness

- SHIMOMURA Home

- Commitment to Sharpness

SHIMOMURA INDUSTRIAL CO., LTD. began its blacksmith business in Sanjo, one of Japan’s leading cutting tool production regions, in 1874. We started from manufacturing agricultural tools such as sickles and hoes. We further evolved the traditional Sanjo cutting tool forging techniques and currently make culinary knives, scissors and slicers mainly out of stainless steel. We aim to deliver “sharp cutting tools” to satisfy those who cook with our tools.

Creating Sharpness

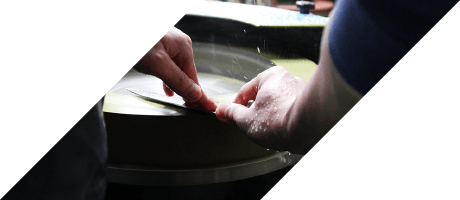

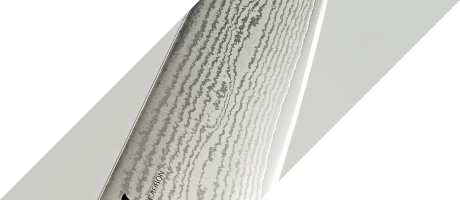

SHIMOMURA INDUSTRIAL adopts in-house production. It takes up to 35 steps to create a knife, and skills of craftsmen are utilized in each process. “Wet grinding” is a sharpening process that directly influences the sharpness of the knife and requires the most skills. The blades are sharpened while water is poured to create an edge called “hamaguri” (blade with a cross-section that resembles a clam). The blades sharpened to a beautiful mirror-finish can cut food effortlessly and maintain their sharpness longer than regular knives.

Pursuing Sharpness

To create “sharp cutting tools”, SHIMOMURA INDUSTRIAL works on improving craftsman’s skills and “developing tools” for creating cutting tools. We demonstrate our technology in working with different materials other than stainless steel such as ceramics and titanium alloys that will not cause metal allergies, and provide cutting tools that satisfy the diversity of food culture and changes in society. We also develop our own machining equipment to improve quality, as well as develop tools to further enhance the skills of the craftsmen, such as adjusting the fineness of whetstones and the values for ideal machining. In addition, in order to convey what a “sharp cutting tool” is, we perform quantitative evaluation on “sharp cutting tools” using our in-house developed measuring microscopes and measuring instruments to determine the blade thickness, angle and load applied upon cutting, which all directly influence the sharpness. The craftsmen study these evaluation data to help improve their skills. SHIMOMURA INDUSTRIAL aims to further improve its cutting tools and bring “sharp cutting tools” to customers’ lives.